When it comes to the PCBA Electronic Circuit BOARD industry, everyone will definitely think of meticulous and cautious descriptions. Indeed, the precision industry needs to be very careful and meticulous no matter which step it is in. Often a seemingly unimportant little detail will lead to the failure of the entire instrument component. scrapped. Just like to pay attention to electrostatic protection when processing pcba, sometimes we will find that the product cannot be used when we use it.

There are many precision electronic components on the PCBA board, and many components are more sensitive to voltage. Shocks above the rated voltage can damage these components. It is difficult to check the PCBA board damaged by static electricity step by step during functional testing. More importantly, some PCBA boards function normally during testing, but when the finished product is used in the hands of customers, occasional defects occur, which brings great hidden dangers to after-sales and affects the company’s brand and goodwill.

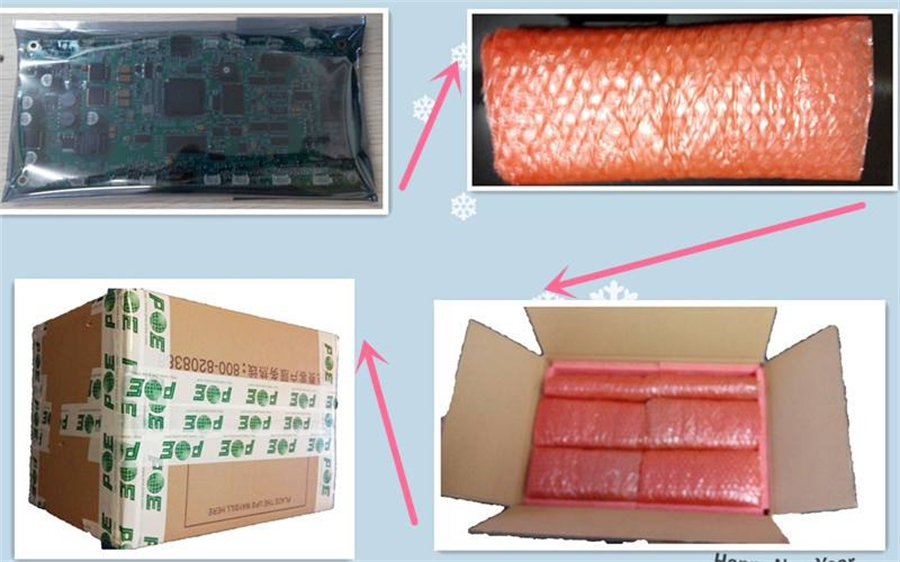

Today we came to the delivery department to check how is our Power Supply Module Electronics PCBA is packaged and shipped.

In fact, the packaging and delivery of PCB Assembling is also very particular, because the bumpy trek on the road may cause the circuit board to suffer some unnecessary wear and tear. In order to avoid these unnecessary wear and tear, our packaging designer will design package of pcba according to certain transportation packaging requirements

Let’s take a look PCB Electronic Circuit Board packaging method

1. ESD foam is used for packaging and transportation.

2. Use anti-static black injection tray for packaging and transportation.

3. ESD Bag for single PCBA

4. Big ESD bag for the whole carton box

How to pack and ship PCBA, Few things draw our attentions

1.Fragile and easily damaged products must be carefully packaged in bubble bags, pearl cotton, electrostatic bags and vacuum bags before transportation.

2. Anti-static packaging Static electricity will break down the chips in the PCBA board. Since static electricity is invisible and intangible, it is easy to generate. Therefore, in the process of packaging and transportation, anti-static packaging must be used.

3. Moisture-proof packaging The surface of the PCBA is cleaned and dried, and the conformal paint is sprayed.

4. Anti-vibration packaging Put the packaged PCBA board into an anti-static packaging box.

When placed vertically, no more than two layers should be stacked upwards, and a baffle should be placed in the middle to keep it stable and prevent shaking.

Post time: Sep-27-2022